Hydraulic Press

Hydraulic Press - Hand/Power Operated Hydraulic Press Machine

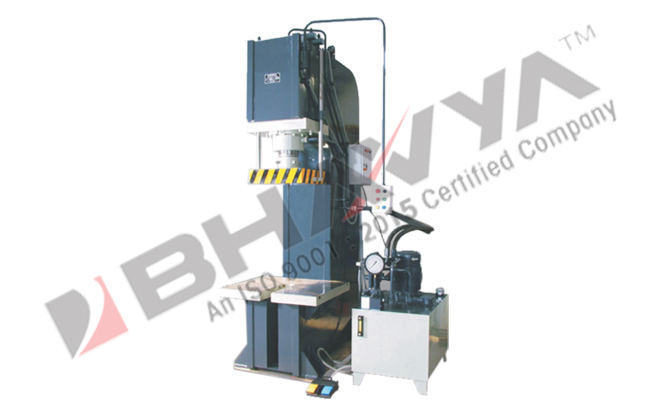

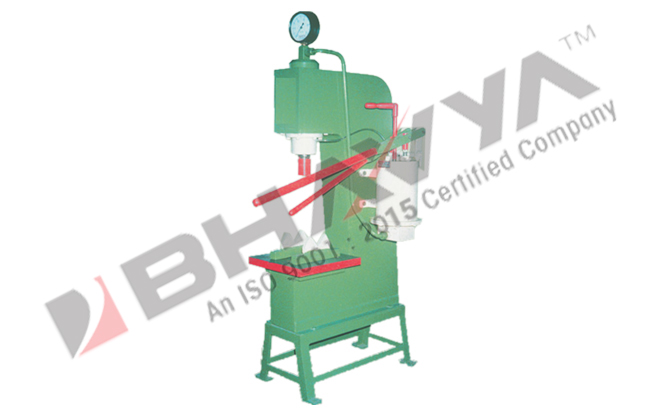

Some models of the hydraulic press include the c-type hand operated press, c-type power operated, H-type power operated press. The pressing equipment is built with great versatility and designed to run at variable strokes and die sizes. They are developed to handle various production needs and different tool sizes as the production demands. The ability to have variable stroke length allows for various applications including punching, straightening, pressing, transfer molding and other applications. Due to the variable stroke length, a wide range of die heights can be used and still be able to maintain the required tonnage during operation.

Bhavya Machine Tools provides optimum quality hydraulic press machine that uses a hydraulic cylinder to generate a compressive force. The presses supplied are powered with specially designed double acting hydraulic cylinders manufactured from high-grade steel. They are used for varied applications, such as- forging, clinching, molding, blanking, punching, deep drawing, and metal forming operations. The presses developed at our facilities boast of having a rigid structure in order to perform accurate operations. They also consist of chevron seals and bronze strip to ensure leak proof operation. The specially designed Power Pack Unit, that powers the hydraulic press, comprise of- Oil Breather (Hydro line), Oil Level Indicator (Hydro line), Suction Strainer (Hydro line), Gear pump (Bosch Rexroth), Flexible Coupling (Jeck Tech), Electric Motor (Crompton / Siemens), Hand Lever operated Direction Control Valve (Bosch Rexroth), Pressure Gauge (Air Master), Return Line Filter (Hydro line), Oil Tank (without oil), Internal & External Pipe Line etc.

Working of a Hydraulic Press Machine

A hydraulic press machine works on pascal’s principle that states that pressure remains constant all over the closed system. The system comprise of two pistons of which one acts as a pump. This pump applies a small amount of mechanical force on a region of small cross-sectional area. On the other hand, the second piston has comparatively larger area that is able to produce substantial amount of mechanical force. When a small amount of force is applied on the smaller piston, a pressure is created that is transmitted to the hydraulic fluid that delivers it to the large piston.

Hydraulic Press Machine

The hydraulic press machine is the staple of the manufacturing industry. With the advent of this versatile tool, you can turn metallic objects into sheets of metals. You can use the machine for sheet manufacturing, deep drawing, punching, forming, molding, and others.

If you are looking for a reliable and cost-effective solution to help you mold the most complex parts, a hydraulic press machine is an ideal solution for your business.

Hydraulic Press Reliable and Cost-Effective Solution for Manufacturing Industry

This customized website concept / text and images are our intellectual property, any company or individual copy whole or a part of the concept is liable to face legal consequences as per the Jurisdiction of Ahmedabad, India.

Copyright© 2025, Bhavya Machine Tools, All rights Reserved Website Design & Digital Marketing by Webmasterindia