Description

Model |

CJK6140B |

| Maximum Swing Over Bed | Ø 400mm |

| Maximum Swing Over Solid | Ø 200mm |

| Maximum Machining Length with Hydraulic Chuck | 550mm |

| Spindle Taper Hole | Ø 58mm |

| Maximum Bar Diameter with Manual Chuck | Ø 58mm |

| Maximum Bar Diameter with Hydraulic Hollow Chunk | Ø 46mm |

| Maximum Bar Diameter with Hydraulic Solid Chunk | None |

| Spindle Head Type | A2-6 |

| Spindle Speed Range | 60-1800rpm |

| Spindle Shift Mode | Inverter |

| Main Moto Power | 7.5Kw |

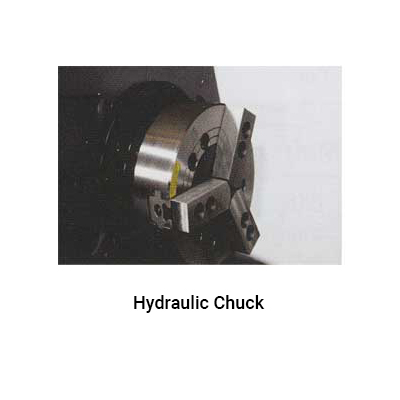

| Chunk Type | Hydraulic Solid (AUTOGRIP-Taiwan) |

| Chunk Size | Ø 250mm |

| Rapid Traverse Speed on X Axis | 5m/min |

| Rapid Traverse Speed on Z Axis | 8m/min |

| Servo Motor Torque on X Axis | 4Nm |

| Servo Motor Torque on Z Axis | 6Nm |

| X Axis Travel | 220mm |

| Z Axis Travel | 600mm |

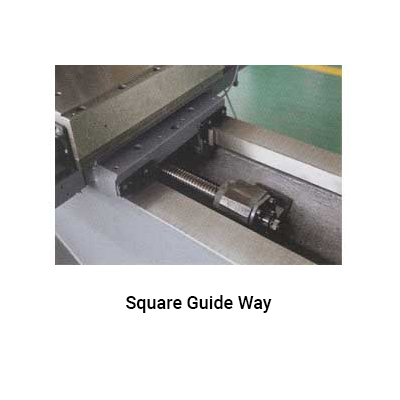

| Guide Way Type | Hardened Box Guide way |

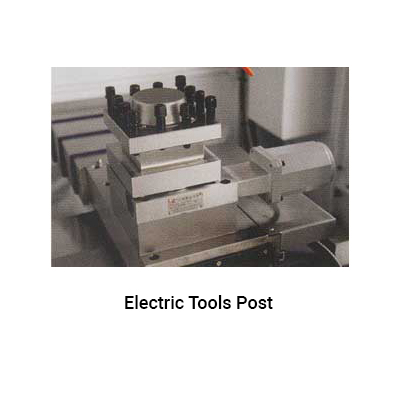

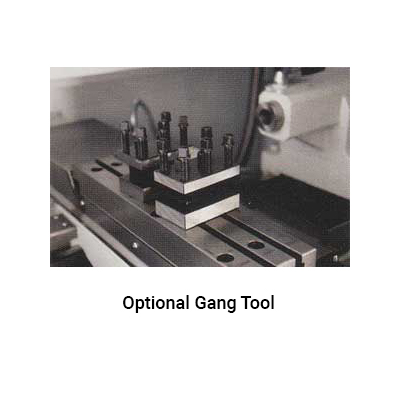

| Turret Type | 4 Station Electric Tool Post + 2 Slot Gang Tool Holder |

| Turret Change Time | 90°/1.5-180°/2.4-270°/3.4-Sec |

| Turning Tool / Boring Bar Size | 25 x 25mm / Ø25mm |

| Tail stock Type | Manual |

| Tail stock Sleeve Diameter/Travel | Ø75/150mm |

| Tail Stock Sleeve Taper | MT5 |

| Weight | 1900KG |

| Dimension – L*W*H | 1950*1180*1560mm |

Sileant Features

- CK6140B-H Mechatronics design is suitable for a variety of machining, such as inner & outer cutting, slotting, all kinds of surface facing & threading. This Machine is widely used in massive production of car & motorcycle parts, valves, electric device & high accurate parts. Carriage with high accurate ball screw provide smooth movements accurate positioning, highly increase the accuracy & stability.

Standard Accessories

250mm Hydraulic Solid True Chuck, Manual Tail Stock, Coolant System, 4-Station Tool Post, Lubrication System

Optional Accessories

| Hydraulic Hollow Chuck-250mm | 40,000.00 |

| Chip Conveyor | 35,000.00 |