Bus Bar Machine 3NC Series

Technical Specifications

| Model | BB-30M | BB-30NC | BB-50NC | BB-80NC | |

|---|---|---|---|---|---|

| Punching | Max. Punching Force (KN) | 300 | 300 | 500 | 800 |

| Punching Diameter Range (MM) | Ø4.3-Ø25 | Ø4.3-Ø25 | Ø4.3-Ø34 | Ø4.3-Ø34 | |

| Max. Thickness (MM) | 12 | 12 | 16 | 20 | |

| Max. Width (MM) | 160 | 160 | 250 | 300 | |

| Shearing / Cutting | Max. Shearing Thickness (MM) | 12 | 12 | 16 | 20 |

| Max. Shearing Width (MM) | 160 | 160 | 250 | 300 | |

| Vertical Bending | Max. Bending Force (KN) | 300 | 300 | 500 | 800 |

| Max. Thickness (MM) | 12 | 12 | 16 | 20 | |

| Max. Width (MM) | 160 | 160 | 250 | 300 | |

| Horizontal Bending | Max. Width (MM) | 100 | 100 | 120 | 250 |

| Max. Angle (Degree) | 90° | 90° | 90° | 90° | |

| Max. Thickness (MM) | 12 | 12 | 16 | 20 | |

| Out Dimension | 1790*1400*1420 | 1790*1400*1420 | 1950*1560*1390 | 2060*1600*1560 | |

| Power | 3 x 4kw | 3 x 4kw | 3 x 5.5kw | 3 x 7.5kw | |

| CNC Precision | Bending Precision | ±1° | ±1° | ±1° | ±1° |

| Repeat Bending Precision | ±0.3° | ±0.3° | ±0.3° | ±0.3° | |

*Specifications are subject to changed without prior notice.

Accessories

Standard :

- Main Drive Motor.

- Separate Foot Switch For Each Station.

- Eight Suitable Die & Punch On Punching Station.

- Unhardened & Ungrounded Suitable Bending Tool.

- Hardened & Grounded HCHCr Blade on Shearing Station.

- Compact Hydraulic Power Pack With Built In Control Panel.

- Guage Stopper On Shearing Station Bending Station & Punching Station.

Optional :

- First Fill Of Oil.

- High Speed Version.

- Special Tools For Bending Station.

- Special Tools For Punching Station.

Features

- P&C Control System & Touch Screen HMI.

- This Is A Highly Productive Machine Suiting To Growing Demand Of Industries.

- International Quality Hydraulic & Electrical Components Ensure Maintenance Free Long Life.

- The Bus Bar Bending, Cutting & Punching Unit Machine Is Technologically Advanced, Compact & Versatile Machine.

- The Machine Is Designed To Cater The Requirement Of Bus Bar Preparation & Almost All Operations Are Included in One Machine.

- The Machine Is Equipped With Three Different & Independent Stations For All These Stations Work Parallel To Contribute High Productivity Of Machine.

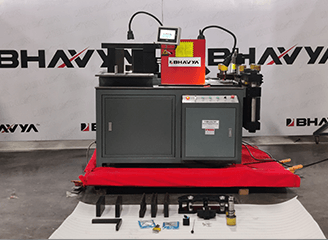

Photo Gallery

Siemens PLC Control System

Electrical (Schneider)

Separate Ele. Motor & Hydraulic Pump for each working station

Relief Valve (YUKEN)

Bus Bar - 50NC

Bus Bar - 50NC

Bus Bar - 50NC

Bus Bar - 50NC

Bus Bar - 80NC

Bus Bar - 80NC

Bus Bar - 80NC

Bus Bar - 80NC