| Model |

|

|

| Bending Capacity |

| In mm |

In mm |

|

|

|

|

|

|

| Approach Pressing Return Speed |

|

|

|

| Packing Dimensions |

| (LxWxH) |

|

Weight Kg |

| PBR 315 |

30 |

1500 |

2x1500 |

3x1250 |

125 |

1050 |

100 |

250 |

200 |

37-5-35 |

3 |

1700x1150x1900 |

1500 |

| PBR 320 |

30 |

2000 |

2x2000 |

3x1250 |

125 |

1550 |

100 |

250 |

200 |

37-5-35 |

3 |

2200x1150x1900 |

1750 |

| PBR 325 |

30 |

2500 |

1.5x2500 |

2x2000 |

125 |

2050 |

100 |

250 |

200 |

37-5-35 |

3 |

2700x1650x2400 |

2100 |

| PBR 415 |

40 |

1500 |

3x15000 |

4x1250 |

180 |

1050 |

100 |

250 |

200 |

55-7-53 |

5 |

1700x1150x1800 |

1800 |

| PBR 420 |

40 |

2000 |

2.5x2000 |

3x1500 |

180 |

1550 |

100 |

250 |

200 |

55-7-53 |

5 |

2200x1150x1800 |

2100 |

| PBR 425 |

40 |

2500 |

2x2500 |

3x1500 |

180 |

2050 |

100 |

250 |

200 |

55-7-53 |

5 |

2700x1150x1900 |

2500 |

| PBR 430 |

40 |

3000 |

1.6x3000 |

2x2500 |

180 |

2550 |

100 |

250 |

200 |

55-7-53 |

5 |

3200x1150x2000 |

3000 |

| PBR 515 |

50 |

1500 |

4x1500 |

5x1250 |

180 |

1050 |

100 |

250 |

200 |

55-7-53 |

5 |

1700x1150x1900 |

2250 |

| PBR 520 |

50 |

2000 |

3x2000 |

4x1500 |

180 |

1550 |

100 |

250 |

200 |

55-7-53 |

5 |

2200x1150x1900 |

2600 |

| PBR 525 |

50 |

2500 |

2.5x2500 |

3x2000 |

180 |

2050 |

100 |

250 |

200 |

55-7-53 |

5 |

2700x1150x1900 |

3000 |

| PBR 530 |

50 |

3000 |

2x3000 |

2.5x2500 |

180 |

2550 |

100 |

250 |

200 |

55-7-53 |

5 |

3200x1150x2000 |

3500 |

| PBR 620 |

65 |

2000 |

4x2000 |

5x1500 |

180 |

1550 |

150 |

330 |

200 |

49-5-33 |

5 |

2200x1200x2000 |

2750 |

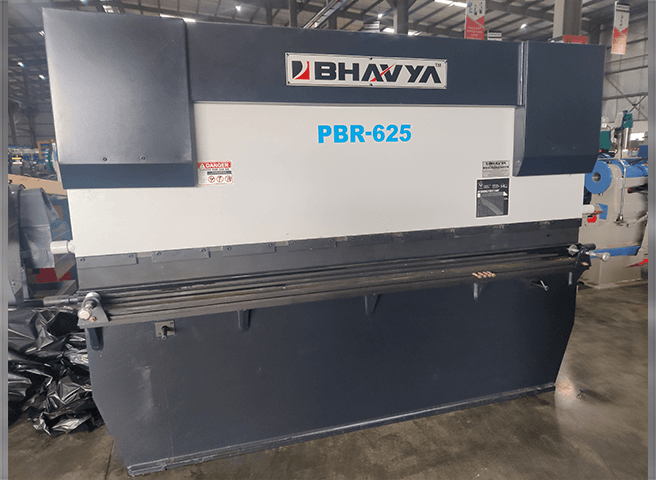

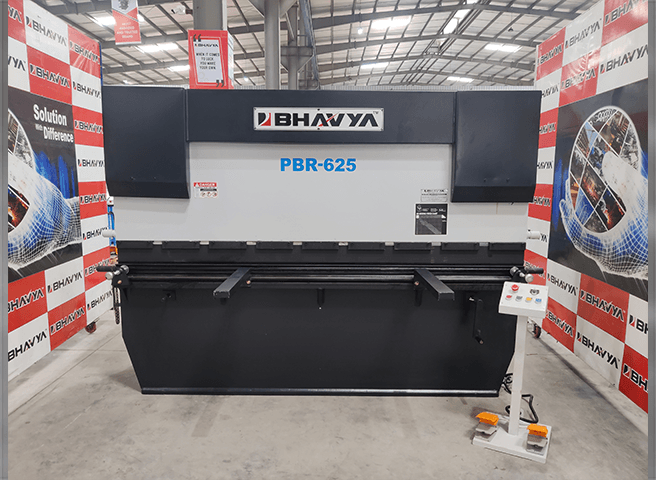

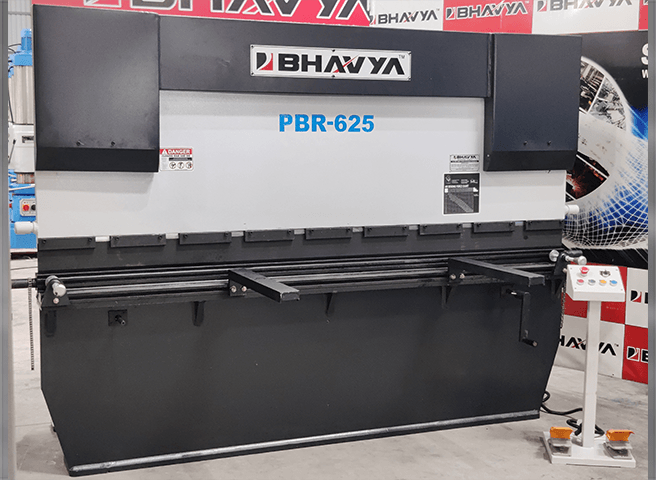

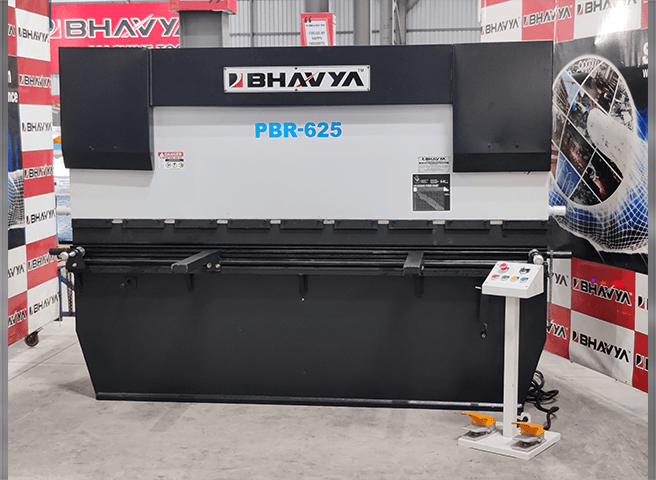

| PBR 625 |

65 |

2500 |

3x2500 |

4x2000 |

180 |

2050 |

150 |

330 |

200 |

49-5-33 |

5 |

2700x1200x2000 |

3250 |

| PBR 630 |

65 |

3000 |

2.5x3000 |

3x2500 |

180 |

2550 |

150 |

330 |

200 |

49-5-33 |

5 |

3200x1200x2000 |

3750 |

| PBR 640 |

65 |

4000 |

2x4000 |

2.5x3000 |

180 |

3100 |

150 |

330 |

200 |

49-5-33 |

5 |

4200x1250x2400 |

4400 |

| PBR 820 |

80 |

2000 |

5x2000 |

6x1500 |

180 |

1550 |

150 |

330 |

200 |

31-5-34 |

7.5 |

2200x1550x2100 |

3700 |

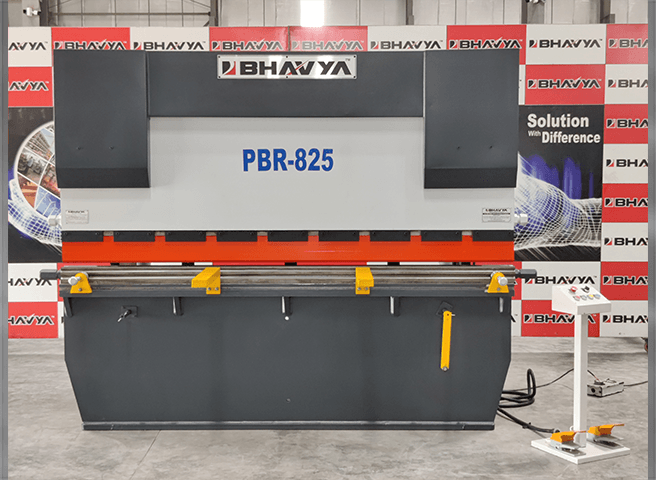

| PBR 825 |

80 |

2500 |

4x2500 |

5x2000 |

180 |

2050 |

150 |

330 |

200 |

31-5-34 |

7.5 |

2750x1550x2300 |

4250 |

| PBR 830 |

80 |

3000 |

3x3000 |

4x2500 |

180 |

2550 |

150 |

330 |

200 |

31-5-34 |

7.5 |

3250x1550x2300 |

4800 |

| PBR 840 |

80 |

4000 |

2.5x4000 |

3x3000 |

180 |

3100 |

150 |

330 |

200 |

31-5-34 |

7.5 |

4250x1650x2500 |

6000 |

| PBR 850 |

80 |

5000 |

5x5000 |

2.5x4000 |

180 |

4100 |

150 |

330 |

200 |

31-5-34 |

7.5 |

5300x1650x2500 |

8000 |

| PBR 1025 |

100 |

2500 |

5x2500 |

6x2000 |

180 |

2050 |

150 |

330 |

200 |

29-04-31 |

10 |

2700x1550x2300 |

4850 |

| PBR 1030 |

100 |

3000 |

4x3000 |

5x2500 |

180 |

2550 |

150 |

330 |

200 |

29-04-31 |

10 |

3250x1550x2300 |

5500 |

| PBR 1040 |

100 |

4000 |

3x4000 |

4x3000 |

180 |

3100 |

150 |

330 |

200 |

29-04-31 |

10 |

4250x1650x2500 |

7000 |

| PBR 1050 |

100 |

5000 |

2.5x5000 |

3x4000 |

180 |

4100 |

150 |

330 |

200 |

29-04-31 |

10 |

5300x1700x2800 |

9000 |

| PBR 1060 |

100 |

6000 |

2x6000 |

2.5x5000 |

180 |

5100 |

150 |

330 |

200 |

29-04-31 |

10 |

6300x1750x2900 |

12000 |

| PBR 1225 |

125 |

2500 |

6x2500 |

8x2000 |

230 |

2050 |

150 |

350 |

300 |

20-04-41 |

15 |

2750x1650x2700 |

5750 |

| PBR 1230 |

125 |

3000 |

5x3000 |

6x2500 |

230 |

2550 |

150 |

350 |

300 |

20-04-41 |

15 |

3250x1650x2500 |

6500 |

| PBR 1240 |

125 |

4000 |

4x4000 |

5x3000 |

230 |

3100 |

150 |

350 |

300 |

20-04-41 |

15 |

4250x1650x2600 |

8000 |

| PBR 1250 |

125 |

5000 |

3x5000 |

4x4000 |

230 |

4100 |

150 |

350 |

300 |

20-04-41 |

15 |

5300x1750x2900 |

11500 |

| PBR 1260 |

125 |

6000 |

2.5x6000 |

3x50000 |

230 |

5100 |

150 |

350 |

300 |

20-04-41 |

15 |

6300x1800x3000 |

14500 |

| PBR 1625 |

160 |

2500 |

8x2500 |

10x2000 |

230 |

2050 |

150 |

350 |

300 |

25-06-42 |

15 |

2750x1800x2500 |

6500 |

| PBR 1630 |

160 |

3000 |

6x3000 |

8x2500 |

230 |

2550 |

150 |

350 |

300 |

25-06-42 |

15 |

3250x1800x2600 |

7500 |

| PBR 1640 |

160 |

4000 |

5x4000 |

6x3000 |

230 |

3100 |

150 |

350 |

300 |

25-06-42 |

15 |

4300x1800x2700 |

7500 |

| PBR 1650 |

160 |

5000 |

4x5000 |

5x4000 |

230 |

4100 |

150 |

350 |

300 |

25-06-42 |

15 |

5300x1850x3000 |

7500 |

| PBR 1660 |

160 |

6000 |

3x6000 |

4x5000 |

230 |

5100 |

150 |

350 |

300 |

25-06-42 |

15 |

6300x1900x3200 |

7500 |

| PBR 2025 |

200 |

2500 |

10x2500 |

12x2000 |

300 |

2050 |

200 |

400 |

300 |

22-04-58 |

20 |

2850x1900x2600 |

10000 |

| PBR 2030 |

200 |

3000 |

8x3000 |

10x2500 |

300 |

2550 |

200 |

400 |

300 |

22-04-58 |

20 |

3350x2050x2750 |

11000 |

| PBR 2040 |

200 |

4000 |

6x4000 |

8x3000 |

300 |

3100 |

200 |

400 |

300 |

22-04-58 |

20 |

4350x2050x2800 |

12500 |

| PBR 2050 |

200 |

5000 |

5x5000 |

6x4000 |

300 |

4100 |

200 |

400 |

300 |

22-04-58 |

20 |

5350x2100x3100 |

15500 |

| PBR 2060 |

200 |

6000 |

4x6000 |

5x5000 |

300 |

5100 |

200 |

400 |

300 |

22-04-58 |

20 |

6350x2200x3500 |

19500 |

| PBR 2530 |

250 |

3000 |

10x3000 |

12x2500 |

300 |

2550 |

200 |

400 |

300 |

22-04-58 |

20 |

3350x2100x2800 |

11500 |

| PBR 2540 |

250 |

4000 |

8x4000 |

10x3000 |

300 |

3100 |

200 |

400 |

300 |

22-04-58 |

20 |

4350x2000x2900 |

20500 |

| PBR 2550 |

250 |

5000 |

6x5000 |

5x4000 |

300 |

4100 |

200 |

400 |

300 |

22-04-58 |

20 |

5350x2150x3200 |

16250 |

| PBR 2560 |

250 |

6000 |

5x6000 |

6x5000 |

300 |

5100 |

200 |

400 |

300 |

22-04-58 |

20 |

6350x2250x3600 |

20500 |

| PBR 3030 |

300 |

12x3000 |

14x2500 |

300 |

2550 |

200 |

400 |

300 |

22-04-58 |

25 |

3350x2150x2900 |

12500 |

| PBR 3040 |

300 |

4000 |

10x3500 |

12x3000 |

300 |

3100 |

200 |

400 |

300 |

30-06-40 |

25 |

4350x2150x2900 |

14000 |

| PBR 3050 |

300 |

5000 |

8x5000 |

10x4000 |

300 |

4100 |

200 |

400 |

300 |

30-06-40 |

25 |

5350x2200x3400 |

19250 |

| PBR 3060 |

300 |

6000 |

6x6000 |

8x4500 |

300 |

5100 |

200 |

400 |

300 |

30-06-40 |

25 |

6350x2300x3800 |

22000 |

| PBR 4030 |

400 |

3000 |

16x3000 |

20x2500 |

300 |

2550 |

250 |

500 |

350 |

25-05-40 |

30 |

3350x2200x3000 |

16000 |

| PBR 4040 |

400 |

4000 |

12x4000 |

16x3000 |

300 |

3100 |

250 |

500 |

350 |

25-05-40 |

30 |

4350x2200x3000 |

20500 |

| PBR 4050 |

400 |

5000 |

10x5000 |

12x4000 |

300 |

4100 |

250 |

500 |

350 |

25-05-40 |

30 |

5350x2250x3600 |

24500 |

| PBR 4060 |

400 |

6000 |

8x6000 |

10x5000 |

300 |

5100 |

250 |

500 |

350 |

25-05-40 |

30 |

6350x2350x4000 |

29500 |

| PBR 5030 |

500 |

3000 |

20x3000 |

25x2500 |

300 |

2550 |

250 |

500 |

350 |

25-5-30 |

40 |

3350x2200x3200 |

19500 |

| PBR 5040 |

500 |

4000 |

16x4000 |

20x3000 |

300 |

3100 |

250 |

500 |

350 |

25-5-30 |

40 |

4500x2200x3300 |

23500 |

| PBR 5050 |

500 |

5000 |

14x5000 |

16x4000 |

300 |

4100 |

250 |

500 |

350 |

25-5-30 |

40 |

5350x2400x3900 |

29500 |

| PBR 5060 |

500 |

6000 |

10x6000 |

14x5000 |

300 |

5100 |

250 |

500 |

350 |

25-5-30 |

40 |

6350x2500x4250 |

34000 |

| PBR 6030 |

600 |

3000 |

25x3000 |

30x2500 |

300 |

2550 |

250 |

500 |

350 |

25-5-30 |

50 |

3350x2200x3300 |

24000 |

| PBR 6040 |

600 |

4000 |

18x4000 |

25x3000 |

300 |

3100 |

250 |

500 |

350 |

25-5-30 |

50 |

4500x2200x3500 |

29000 |

| PBR 6050 |

600 |

5000 |

14x5000 |

18x4000 |

300 |

4100 |

250 |

500 |

350 |

25-5-30 |

50 |

5350x2300x3700 |

34500 |

| PBR 6060 |

600 |

6000 |

12x6000 |

14x5000 |

300 |

5100 |

250 |

500 |

350 |

25-5-30 |

50 |

6350x2600x4350 |

41000 |

*Specifications are subject to changed without prior notice.